By showcasing high-quality components at UTECH Europe 2018, Hennecke demonstrated its expertise in all PU applications. Visitors to the leading international exhibition and conference for the global polyurethane industry were particularly interested in the high-quality insulation for hot water storage tanks which ensures maximum...

Hennecke's participation at this year's JEC trade fair in Paris, the most important specialist trade fair for fibre composites, was more than satisfactory. Hennecke's presence at the trade fair focused on product innovations in the area of wet shots. Amongst other things, the composite specialists presented a new wide shot...

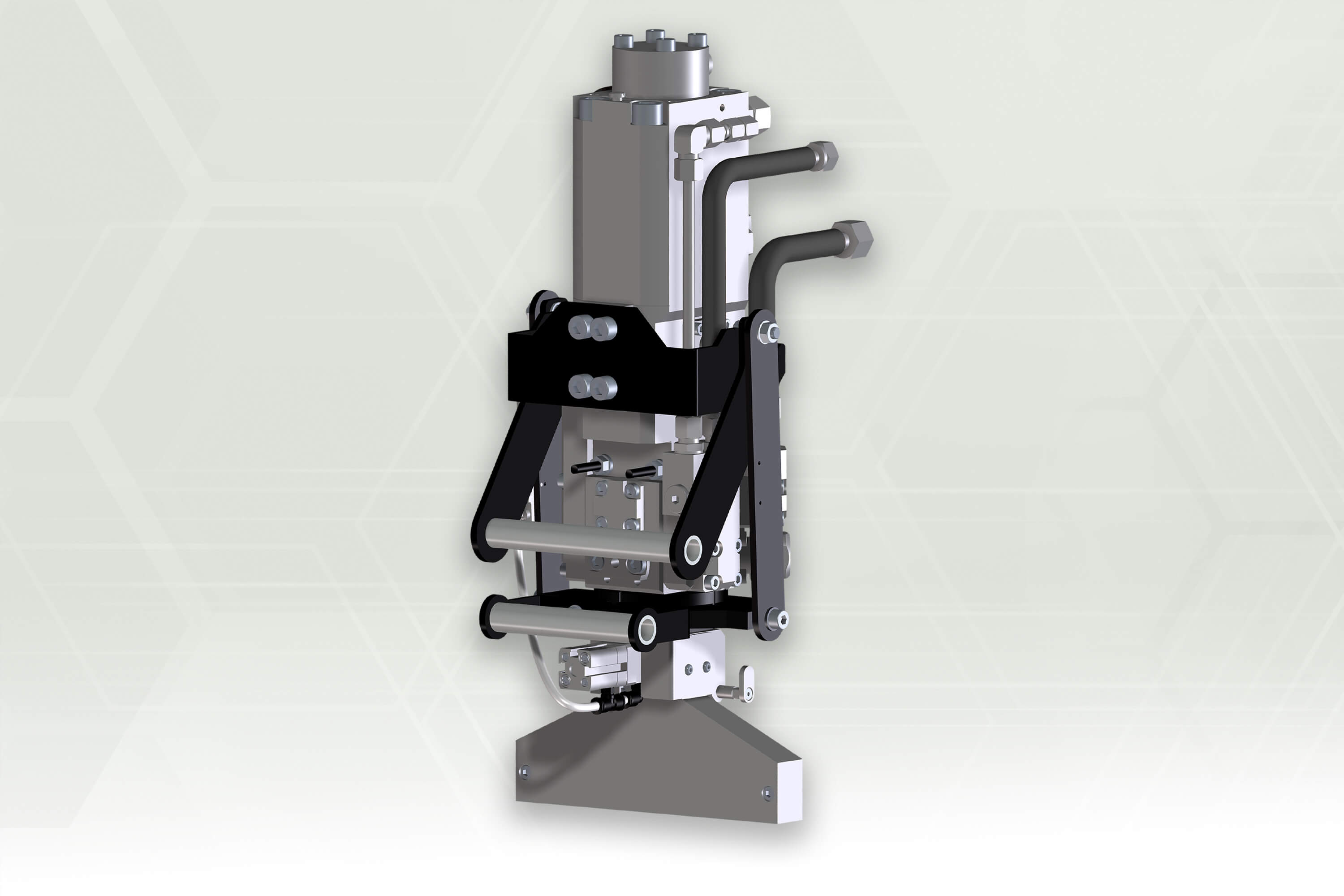

Hennecke has made decisive advancements in so-called wet compression molding (WCM) technology through extensive process knowledge and on the basis of various customer requirements.

WCM technology represents an efficient production method for the high-volume production of fiber-reinforced structural components and is...

The use of Intermediate Bulk Containers (IBC) for the transport and storage of fluid chemicals is increasing across the world. In the processing of polyurethane as well, the 1000 kg drums offer significant advantages. The new, modular IBC station from Hennecke greatly simplifies handling of the containers, ensures utmost process...

The Hennecke Group has been very successfully building spraying plants with the well-established PUR-CSM spray technology for various automotive and non-automotive applications and supplying them to global markets for a number of years. The PUR-CSM spray technology is renowned worldwide for its considerable benefits: one feature is...

New Hennecke horizontal carriage mould carrier for semiautomatic production of hot water tanks

In modern house technology, going without a hot water tank is unthinkable. With state-of-the-art devices, contractors and heating modernisers can provide hot water with great energy efficiency. Thanks to high-...

Fast and uncomplicated colour change for surface finishing of decorative elements and functional elements

Hennecke is a recognized specialist when the task at hand is generating scratch-resistant and high-quality surfaces on injection moulded components using polyurethane or polyurea systems. With the new...

Hennecke is acquiring all shares of OMS Group. The legal closing of the transaction will be complete by the end of December 2017. “With this acquisition, two technological leaders in the polyurethane machinery business are joining forces to open up opportunities for stronger growth”, emphasizes Rolf Trippler, Managing...

At Fakuma 2017 (hall A5, stand 5210), Hennecke is introducing the new machine system COLOURLINE for the first time. Based on the CLEARMELT technology, users can now also employ the colour systems to create scratch-resistant and high-quality surfaces on injection-moulded parts. Here, the intelligent plug-and-play system "MULTI-...

With eight partners, 21 specialists, and 28 weeks of development time until the potential start of series production, Hennecke introduced the R.A.C.E. project at the K 2016 in Düsseldorf. At the fair, the PUR specialist presented a complex hollow construction part suitable for mass production for the KTM 1290 Superduke, and its...

The fields designated with (*) are mandatory fields. We require this information in order to be able to reply to you.