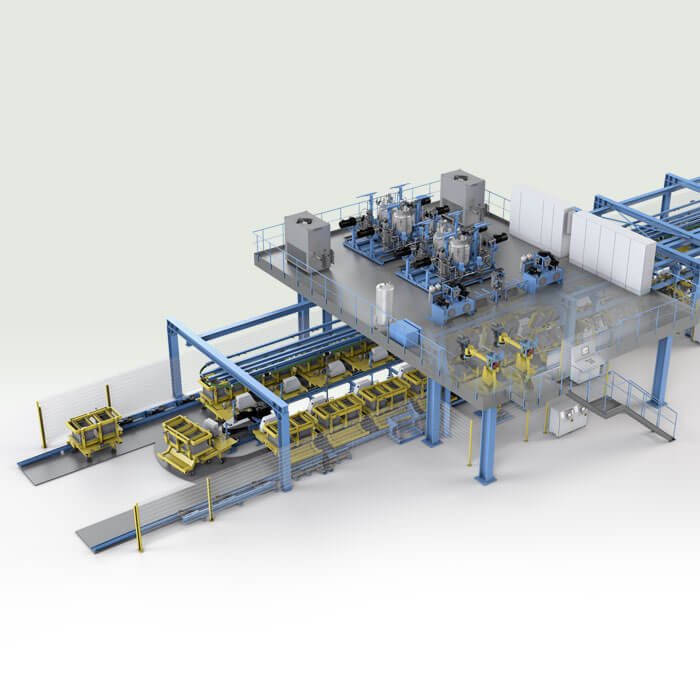

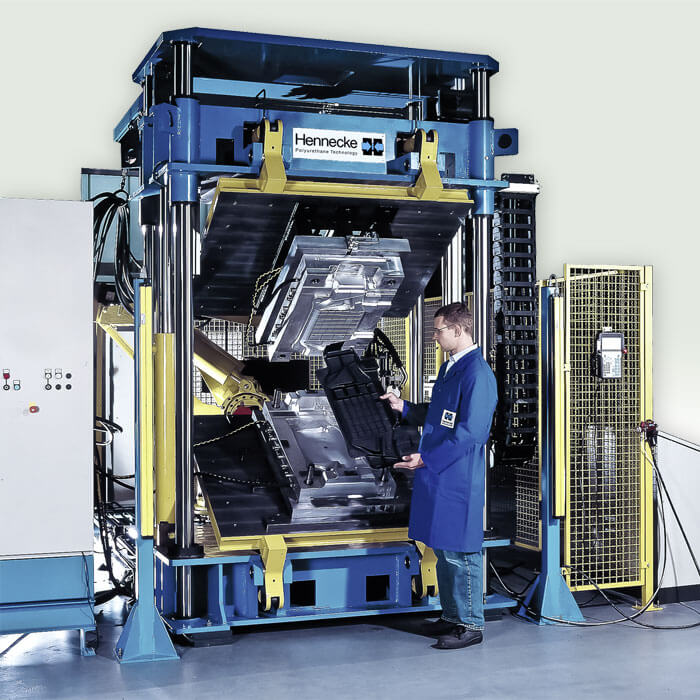

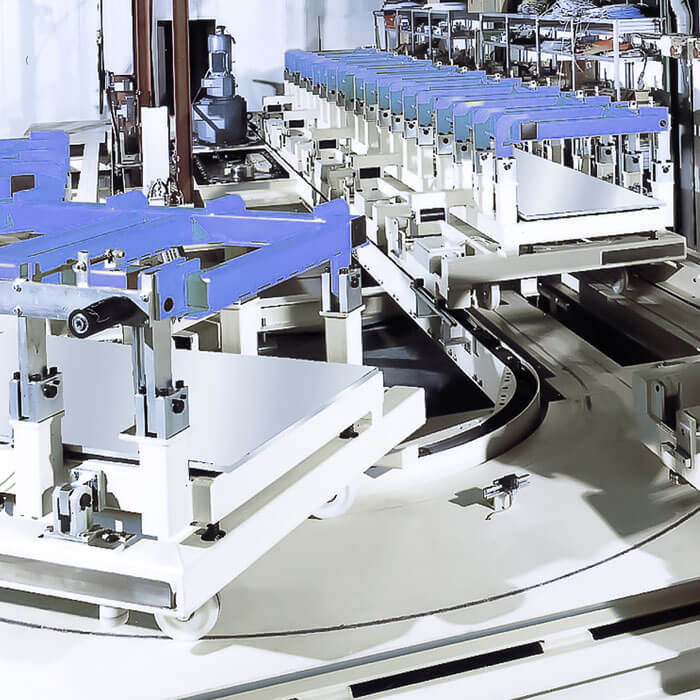

Considering the fact that there is now a vast range of models but fewer lot sizes and shorter production cycles, systems are required that can be used to manufacture different products in all kinds of quantities in an extensively automated and, above all, profitable manner. Our manufacturing know-how in this field gives you a high degree of investment security. This is also true for special requirements. Apart from oval conveyors and rotary tables, Hennecke can also supply highly specialized TRANSFER, TRANSFLEX, SHUTTLE and POLYSHUTTLE lines.