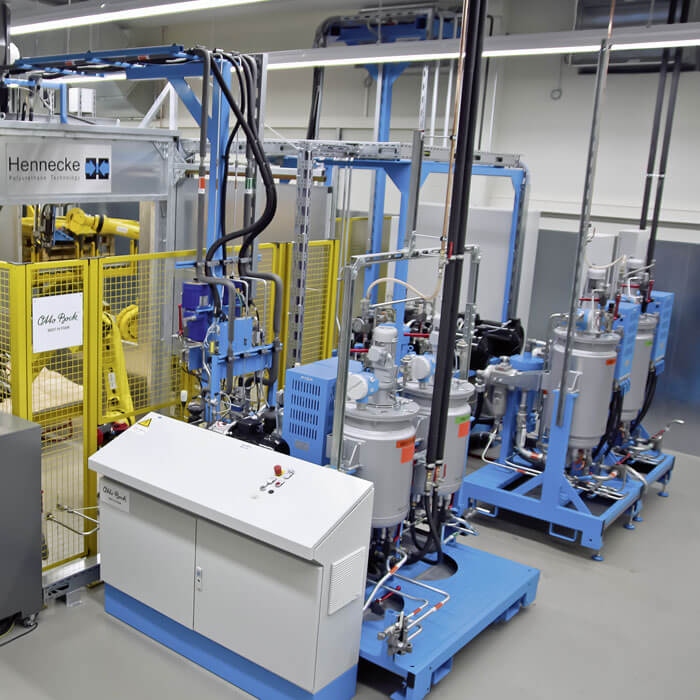

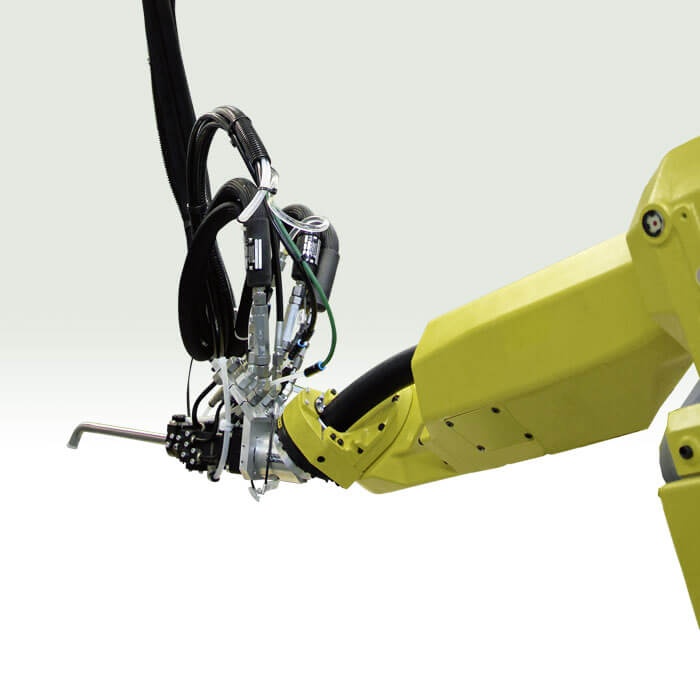

The innovative and forward-looking PUR-CSM polyurethane spray-moulding technology has been successful in practical use for over fifteen years now, setting new standards in PU processing ever since – whether in special-purpose applications or mass production. Among users, PUR-CSM has become synonymous with efficiency, flexibility and process reliability. Supplementing the engineering portfolio of advanced spray technology, customized mixheads have been developed along with various high-efficiency processing cells and machine designs. Together, these solutions provide suitable configurations for small and large production volumes and are tailored to fit the requirements of spray technology and its special parameters.

In the spraying process, PUR-CSM lines enable production of fibre-reinforced components or compound mouldings made of unfilled or filled PUR systems. As the basis and development platform for all known PUR-CSM products, the innovative systems technology offers exceptional competitive...

More Information

The use of fiber-reinforced composites often starts when the properties of conventional materials no longer meet the customer's requirements. Laminate is frequently used in three-layer sandwich constructions. Here the two facings are composed of a fiber composite material and are spaced...

More Information

One forward-looking yet eco-friendly major application of PUR-CSM technology lies in the substitution of GFRP mouldings such as bathtubs and shower trays. Here, the use of PUR-CSM meets the most exacting demands in terms of production flexibility, reproducible part quality and material...

More Information

The benefits of spray technology will pay off especially when it comes to finishing complex parts such as dashboards or door panels. A layer of aliphatic paint is initially applied by In-Mould Coating (IMC). This UV-resistant coating is then reinforced with a sprayed aromatic polyurethane....

More Information

The fields designated with (*) are mandatory fields. We require this information in order to be able to reply to you.