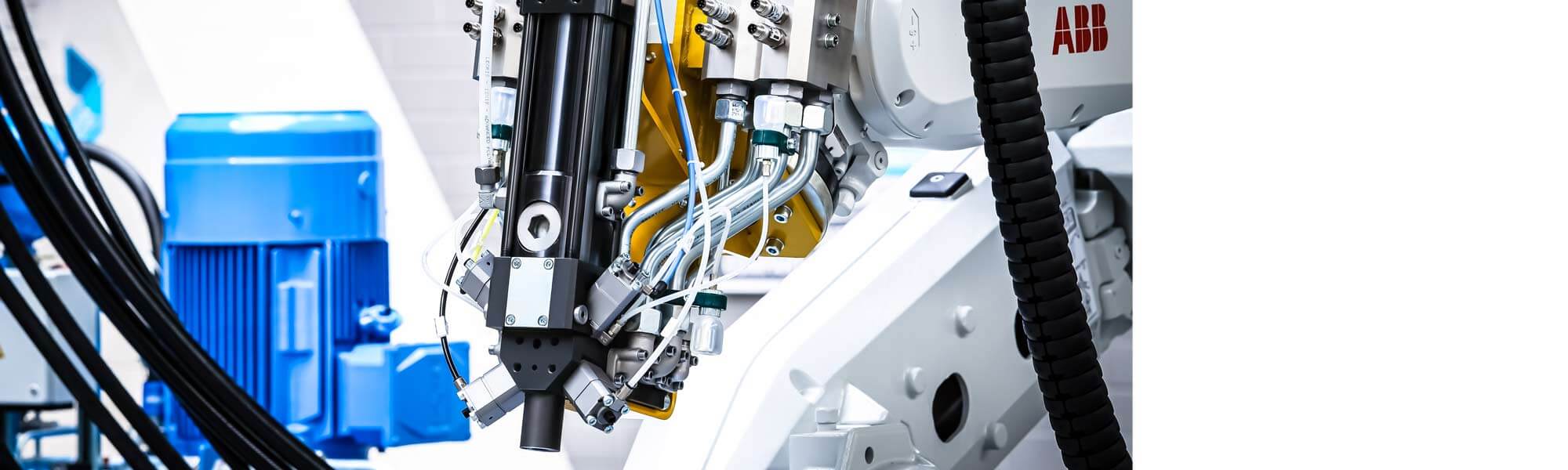

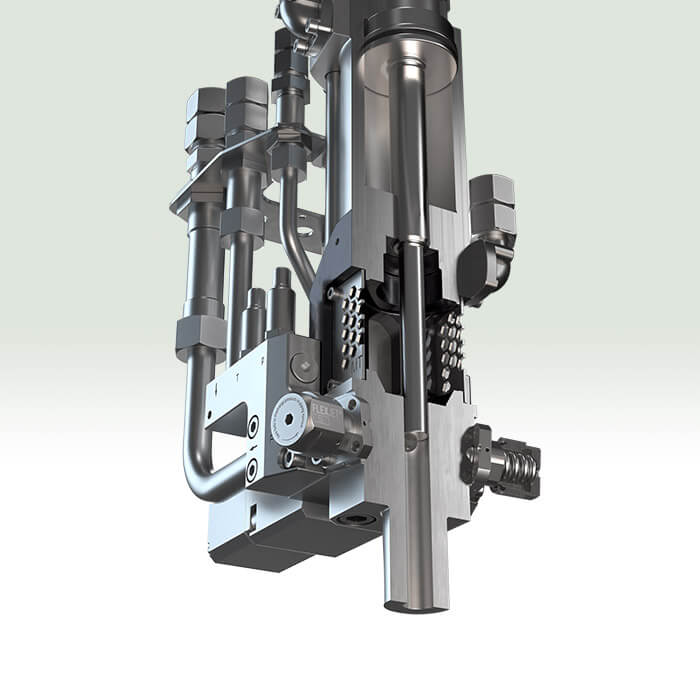

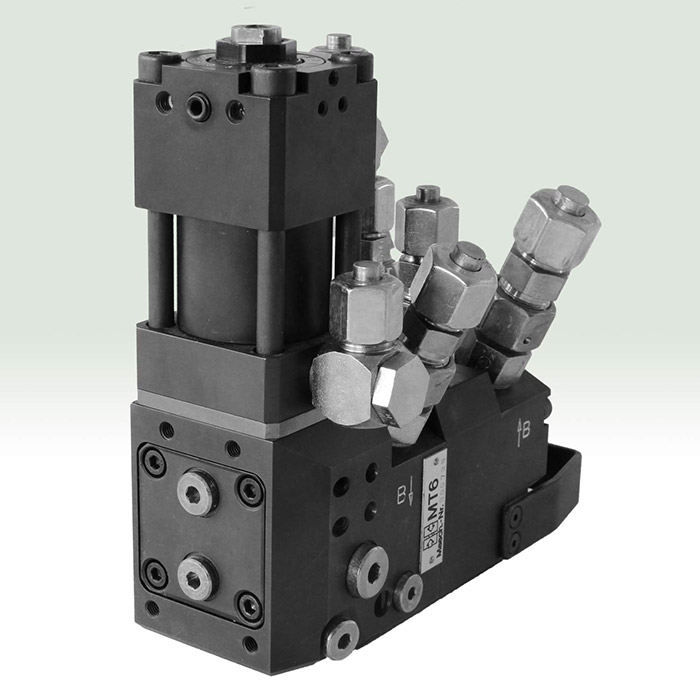

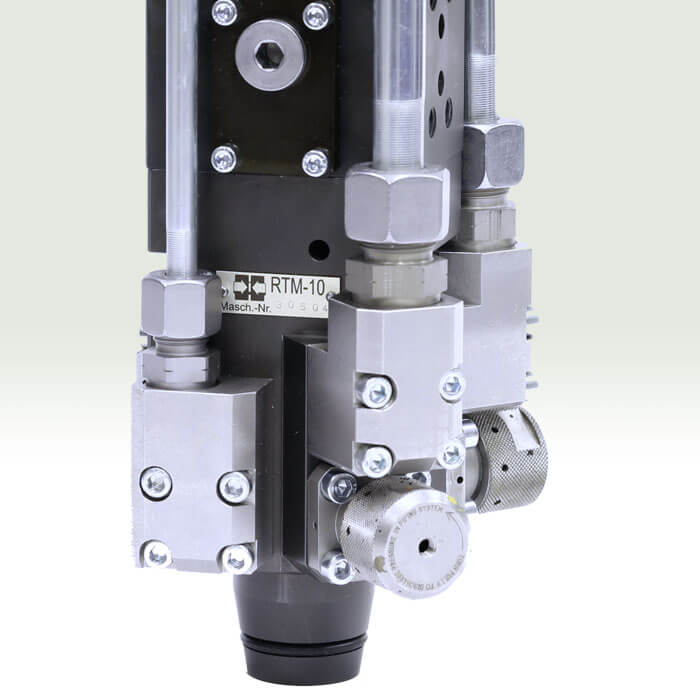

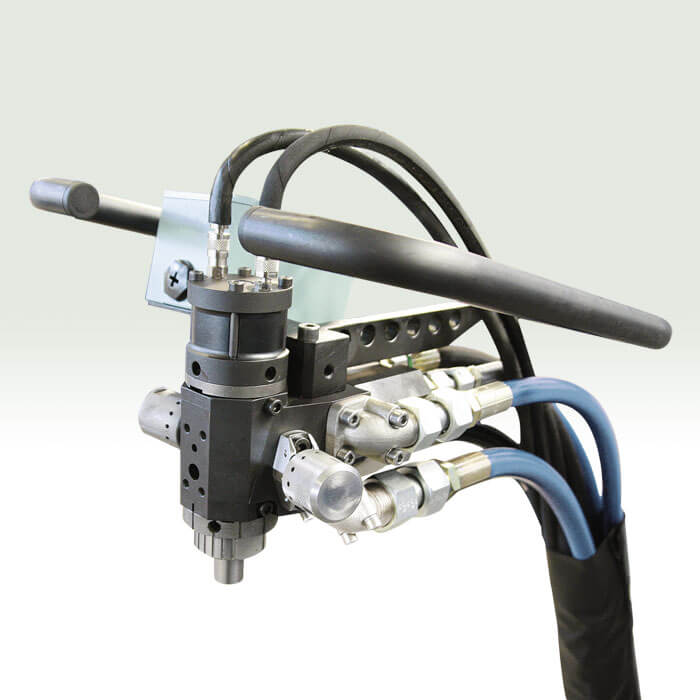

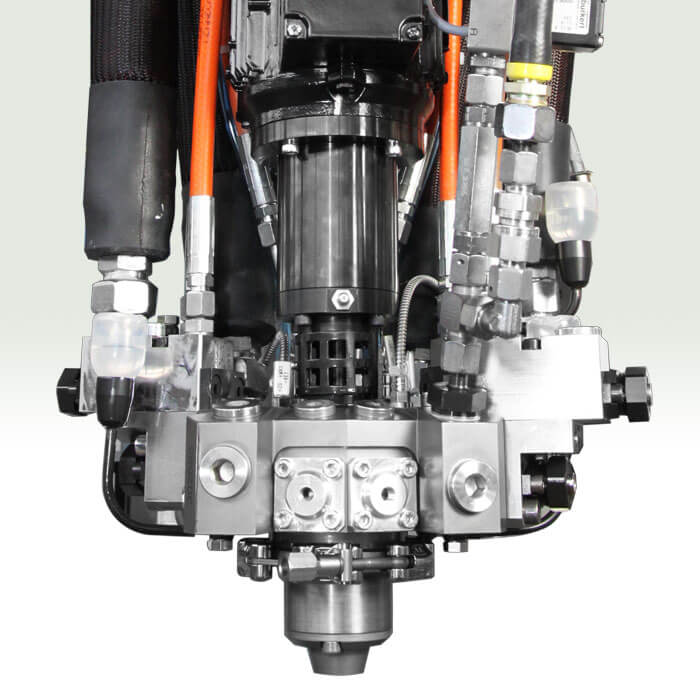

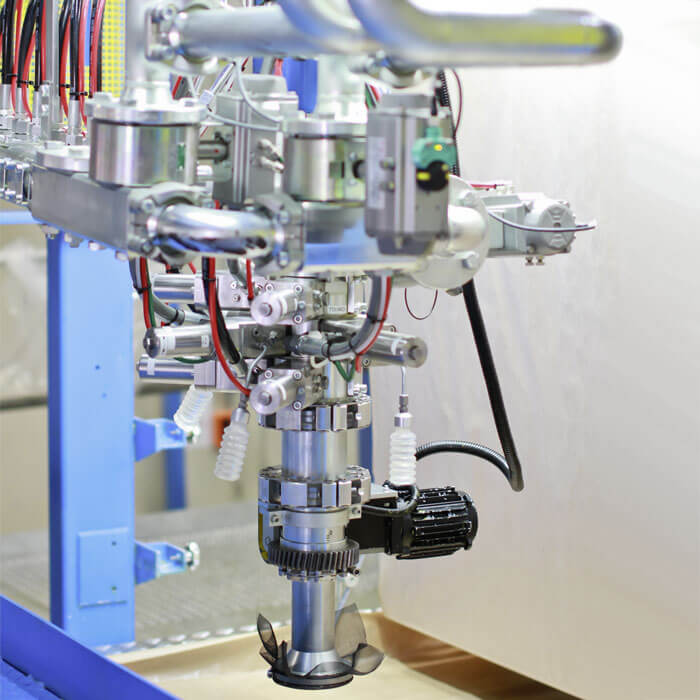

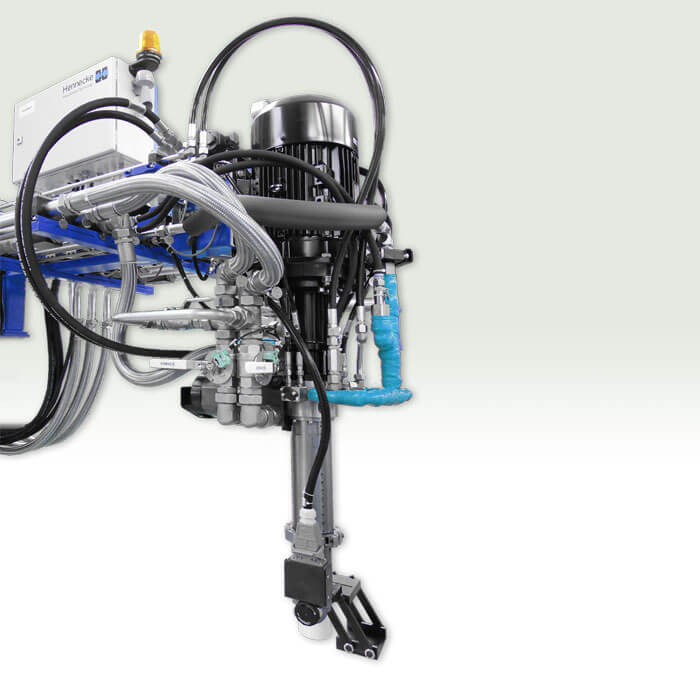

Whether rigid or flexible, integral skin, filling or energy-absorbing foam is concerned, Hennecke GROUP has the appropriate high-pressure polyurethane mixhead for almost every application that requires mixing based on the impingement injection principle, from standard to specific applications. Variable sizes and injector shapes as well as a comprehensive range of accessories ensure that the mixheads can be adapted to suit a great variety of conceivable requirements - including yours!