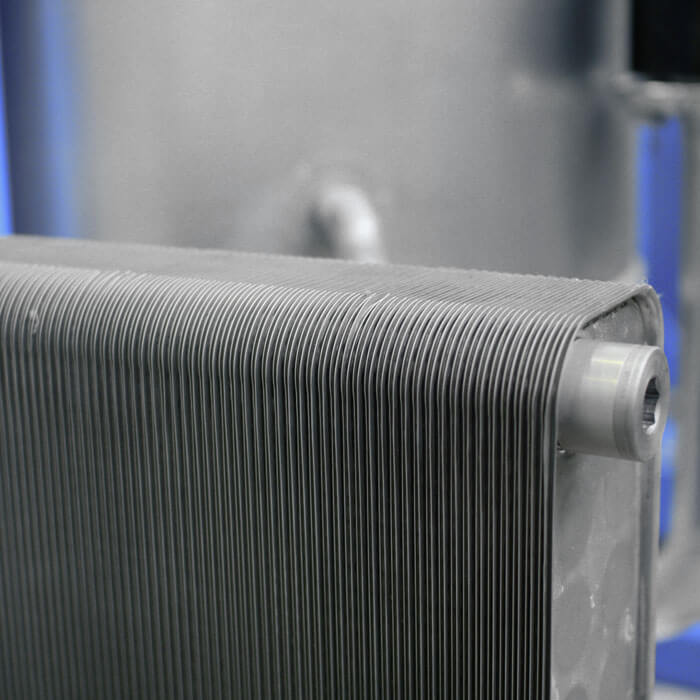

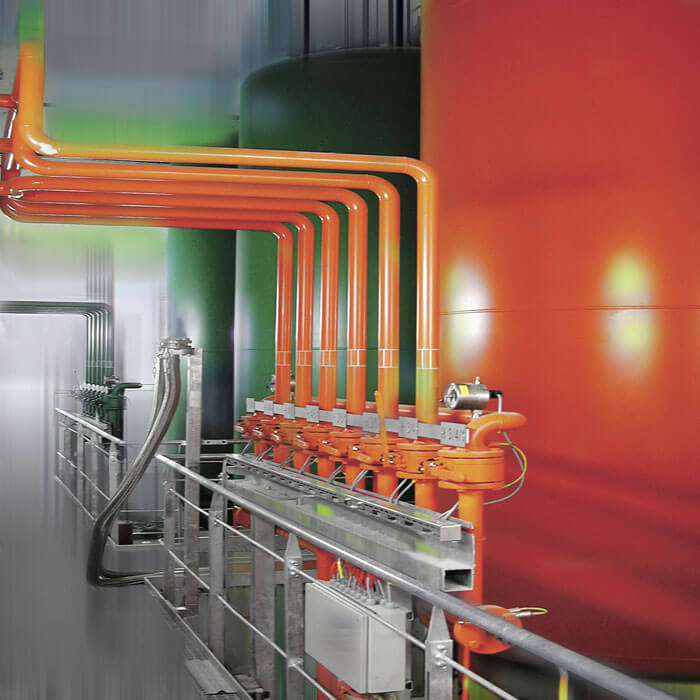

For the end product to achieve the desired properties, it will be necessary in some applications to condition the raw material systems used by a metered additon of technical gases, blowing agents or solids such as nitrogen, natural carbon dioxide, PENTANE or calcium carbonate. To this end, Hennecke offers proven peripheral equipment ensuring the desired production results from both an economic and ecological perspective. At the user's request, our machinery and equipment can also be supplied with conditioning and manipulating systems for the raw materials used, e.g., to control product properties by a metered addition of fluids and solids.